PRODUCTION

TECHNOLOGIES

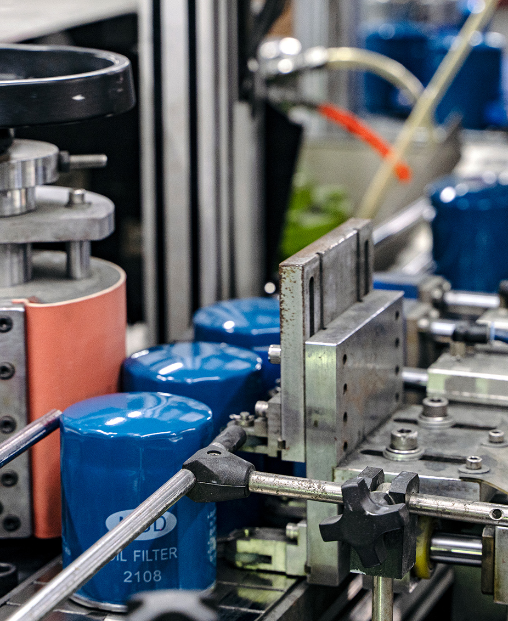

VSARS has advanced and reliable production technologies that allow us to create quality products and contain production times and costs to be competitive in an increasingly demanding market.

VSARS leverages the industry-leading automation level of manufacturing,

which allows us to produce large batches of automotive filter products

With unsurpassed consistency and perfection.

90% of the processes necessary to produce an air, oil or fuel filter are carried out in our factories, starting with the production of the filtration elements and the molding of metal and polyurethane components, passing through the assembly phases up to to the final inspection of each finished product.

A fundamental part of our production process is the constant control of every detail. We are equipped with in-line testing systems that verify 100% of the filters produced and we have a laboratory inside where checks are carried out on the incoming materials and functional tests on the finished products.

Total area 11.000 m²

Covered area 4,000 m²

Three production line for oil filters and spin-on fuel filters

Two production line for oil filters and ecological fuel filters

A laboratory controls and tests on incoming materials and finished products

Total area 20.000 m²

Covered area 5.000 m²

Two production line for radial air filters

Four production lines for panel air filters

A production lines for cabin air filters

Central logistics warehouse

Total area 11.000 m²

Covered area 4,000 m²

A production line for fuel pump filters

A production line for fuel injections

A laboratory controls and tests on incoming materials and finished products

Total surface 5,000 m²

Storage capacity 3,000,000 filters

Order fulfillment ability

with a rate of 95% of the ordered

Four guaranteed shipments per day